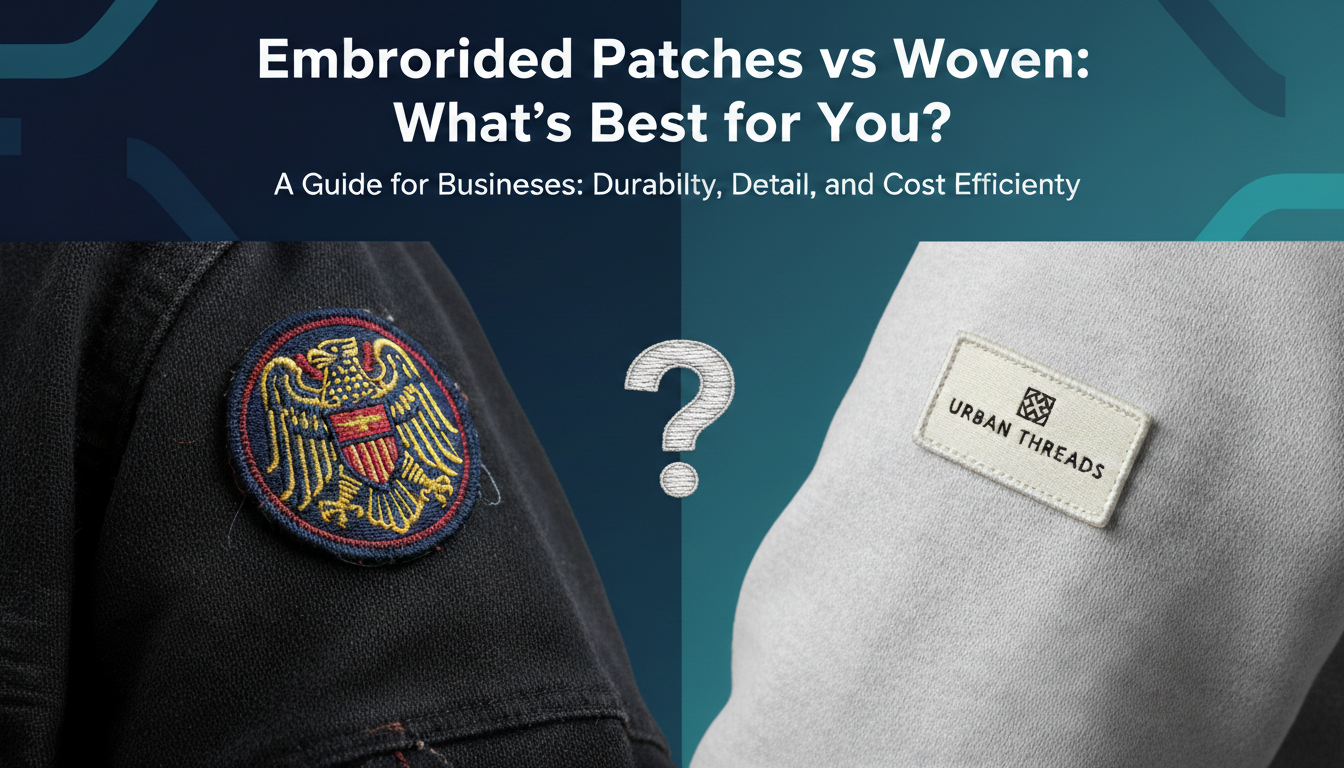

Embroidered Patches vs Woven: What’s Best for You?

Choosing between embroidered custom patches and woven custom patches is not just a design decision. For B2B buyers, it directly affects cost efficiency, durability, brand consistency, and end user satisfaction. Uniform suppliers, apparel brands, promotional product companies, and resellers all face this decision when sourcing patches in bulk.

This long form guide is written to help businesses make the right choice based on real production differences, not marketing language. It balances informational intent with transactional clarity so you can confidently move from research to ordering.

.png)

Quick Overview for Buyers

Embroidered Custom Patches

Raised textured stitching

Thicker thread

Best for bold logos and simple artwork

Preferred for uniforms and outerwear

Long lasting and rugged

Woven Custom Patches

Flat smooth surface

Fine woven threads

Best for detailed designs and small text

Preferred for fashion and labels

Clean and modern appearance

If you are sourcing patches for heavy use garments, embroidered patches usually perform better. If your branding relies on detail clarity, woven patches are the stronger option.

Complete Guide

What Are Embroidered Custom Patches?

Embroidered custom patches are made by stitching thick threads onto a fabric backing. The stitching does not fully cover the base fabric, which creates depth and a textured surface.

Key Features of Embroidered Patches

Thread coverage typically between 50 and 75 percent

Raised stitching for a traditional look

Strong structure suitable for repeated wear

Clean borders using merrowed or heat cut edges

Popular B2B Applications

Embroidered patches for uniforms in military, law enforcement, security, and corporate sectors

Embroidered patches for jackets including varsity, biker, and workwear

Embroidered logo patches for brand recognition

Promotional merchandise and resale items

Why Businesses Choose Embroidered Patches

Recognized as premium and durable

Hold shape after washing and long term use

Ideal for large volume orders with consistent quality

Available as iron on embroidered patches and sew on embroidered patches

Working with an experienced embroidered patches manufacturer ensures consistent stitch quality, color accuracy, and reliable delivery timelines for bulk orders.

What Are Woven Custom Patches?

Woven custom patches are produced by weaving fine threads together on a loom. Instead of stitching on top of fabric, the design is built directly into the patch surface.

Key Features of Woven Patches

Very thin thread for high resolution detail

Flat smooth finish

Excellent clarity for small text and complex artwork

Lightweight and flexible

Popular B2B Applications

Custom woven labels for clothing

Fashion brands and private label apparel

Woven logo patches for caps and accessories

Branding labels for retail products

Why Businesses Choose Woven Patches

Sharp detail reproduction

Consistent appearance across large production runs

Ideal for modern minimalist branding

Available as iron on woven patches and sew on woven patches

Fashion and apparel brands often work directly with a specialized woven patches manufacturer to maintain detail accuracy and brand consistency.

Embroidered vs Woven Patches: In Depth Comparison

Design Detail and Text Readability

Woven patches clearly outperform embroidered patches when artwork includes small text, fine lines, or detailed symbols. Embroidered patches can lose clarity due to thicker thread limitations.

Best choice for detail: Woven Custom Patches

Texture and Visual Presence

Embroidered patches have a raised surface that adds dimension. This makes them more noticeable on jackets, uniforms, and outerwear.

Best choice for texture: Embroidered Custom Patches

Durability and Wear Resistance

Both options are durable, but embroidered patches handle abrasion and repeated washing better, making them ideal for workwear and uniforms.

Best choice for durability: High quality embroidered patches

7. Email Marketing

Cost Efficiency for Bulk Orders

Pricing depends on size, color count, and design complexity.

Embroidered patches bulk orders are cost effective for simple bold designs

Woven patches bulk orders are more efficient for detailed artwork without increasing stitch density costs

For B2B buyers, ordering directly from manufacturers reduces per unit pricing.

Attachment Options

Both patch types support:

Iron on backing

Sew on backing

Velcro backing

Adhesive backing

Your choice depends on garment type and end user requirements rather than patch construction.

Industry Based Recommendations

Uniform and Workwear Suppliers

Choose embroidered patches for uniforms for durability, authority, and long term performance.

Fashion and Apparel Brands

Choose custom woven patches or woven label patches for clean branding and detailed logos.

Promotional Product Companies

Embroidered logo patches work well for giveaways and branded merchandise where durability matters.

Retailers and Resellers

Offering both embroidered and woven options helps meet diverse customer preferences.

Choosing the Right Patch Manufacturer

The success of your patch order depends heavily on the manufacturer you choose.

A reliable embroidered patches manufacturer or woven patches manufacturer should provide:

Direct factory production

Bulk order capabilities

Clear sampling and approval process

Multiple backing options

Quality control at every stage

This is especially important for long term B2B partnerships and repeat orders.

Ordering Tips for Business Buyers

Finalize artwork before production to avoid delays

Choose size carefully to balance visibility and cost

Request pre production samples for bulk orders

Match backing type with garment fabric

Plan lead times for large quantity production

Interactive Quizzes

Engage and qualify leads

ROI Calculators

Demonstrate value clearly

Interactive Infographics

Visualize complex data

Frequently Asked Questions

Are embroidered patches better than woven patches?

Neither is universally better. Embroidered custom patches are better for bold designs and durability. Woven custom patches are better for fine detail and text clarity.

What is the difference between embroidered and woven patches?

Embroidered patches use stitched threads on fabric, creating a raised texture. Woven patches use fine threads woven together, creating a flat detailed surface.

Which patches are best for uniforms?

Embroidered patches for uniforms are preferred due to durability and professional appearance.

Are woven patches durable?

Yes. Woven patches are durable for everyday apparel but are better suited for fashion and branding rather than heavy duty workwear.

Can woven patches be ironed on?

Yes. Iron on woven patches are commonly used and suitable for most garments when applied correctly.

Which is better for logo patches?

Simple logos work best as embroidered logo patches. Logos with small text or intricate detail work better as woven logo patches.

Can I order patches in bulk?

Yes. Both embroidered patches bulk and woven patches bulk orders are common for B2B buyers and reduce overall cost.

Helpful Comments

PatchLover22

March 15, 2025I tried this method with felt fabric and it worked beautifully! The patches have lasted through multiple washes.

CraftyMom

February 28, 2025Adding a thin layer of fabric paint around the edges really helps prevent fraying over time. Great tutorial!

DIYenthusiast

April 2, 2025For those having trouble with the adhesive, I found that pressing for 10 seconds, letting it cool slightly, then pressing again for another 10 seconds works better than one long press.